February 17, 2025

At the MANN+HUMMEL Technology Center

New test bench enables solutions to increase efficiency and extend the lifetime of fuel cell components

Ludwigsburg, February 17, 2025 – Hydrogen fuel cells are considered a promising alternative to classic battery-electric drives. The role they can play on the road to a zero-emission future depends largely on their performance and lifetime. The regulation of the humidity level in the fuel cell membrane is an important parameter that a humidifier assumes. MANN+HUMMEL has developed a test bench that enables tests with humidifiers under real conditions and can thus extend the lifetime of fuel cell components.

Function test of two test objects

Function test of two test objects

Fuel cells are energy converters that convert the chemical energy of a fuel, usually in the form of hydrogen, into electrical energy. The energy is produced by the separation of the electrons from the hydrogen protons, which diffuse through a membrane while the electrons flow through an electric circuit. Powered by green hydrogen, fuel cell vehicles only emit water and heat, thus making a significant contribution to the reduction of CO2, nitrogen and particulate emissions. Among the various fuel cell types, those with polymer electrolyte membranes (PEM) have established themselves as the first choice for mobility applications due to their high power density. The correct moisture level of this membrane plays a decisive role in its performance and durability. This is because adequate humidification ensures efficient proton transfer in the PEM. Too little moisture can dry out the membrane, which affects the performance of the fuel cell. Advanced water management strategies using humidifiers therefore balance the humidity and guarantee efficient and reliable operation.

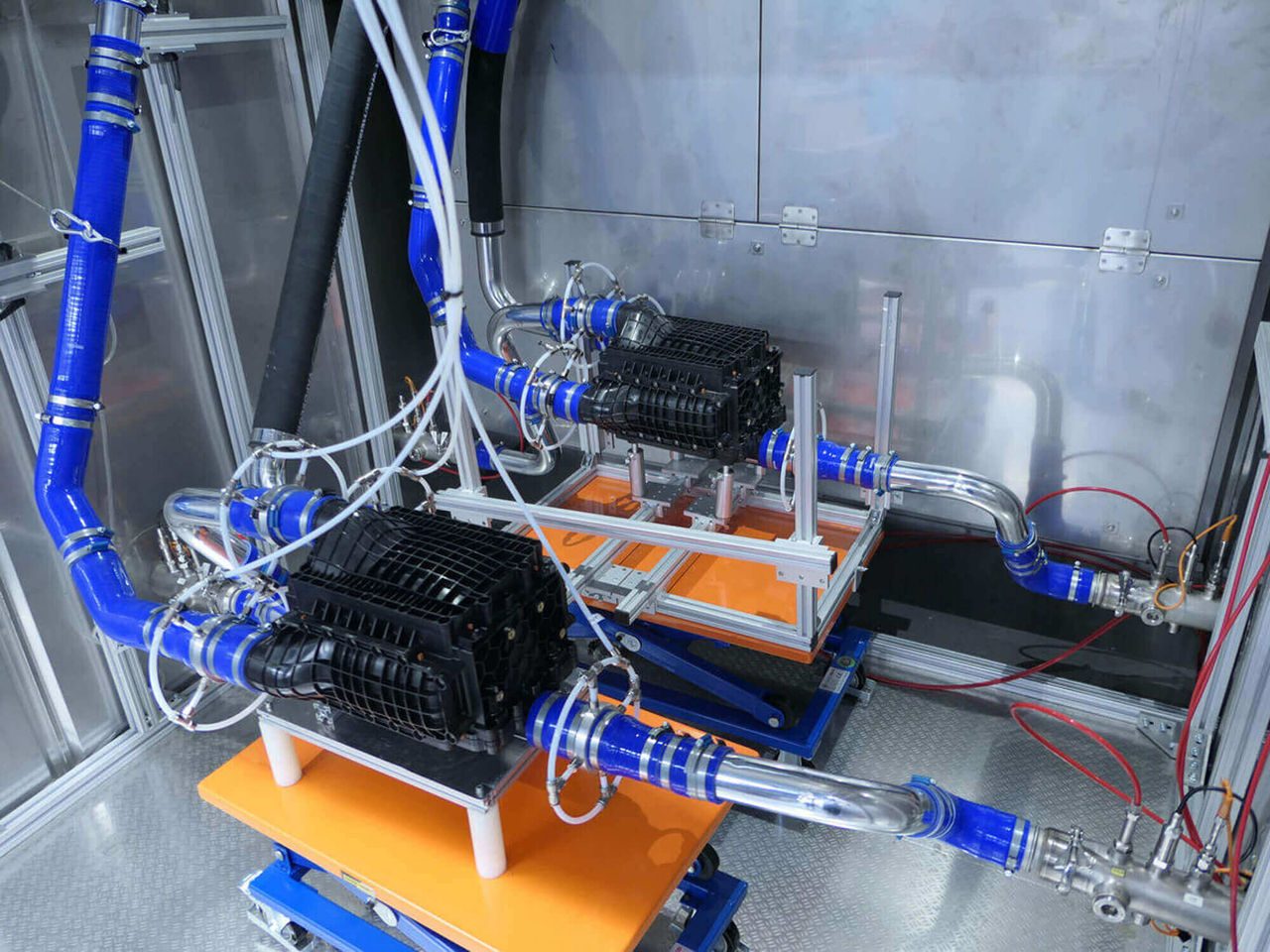

Humidifier test bench in Ludwigsburg - inside view

Humidifier test bench in Ludwigsburg - inside view

Test bench tests humidifiers under real conditions

The newly developed test bench installed in the technology center at the headquarters in Ludwigsburg, means that MANN+HUMMEL can measure and optimize the efficiency and lifetime of fuel cell components, in particular humidifiers, under real conditions. The complex structure of the system enables simultaneous testing of several components in a temperature range of -40 to +120 degrees Celsius without time-consuming set-up. This allows real operational conditions to be mapped and different humidifier variants to be compared with each other. Automated measurement methods allow not only performance tests but also endurance tests of over a thousand hours. In this way, the moisture transfer, the differential pressure and the tightness of the system can be measured at varying temperature, humidity and pressure cycles. “The test bench humidifies the air by adding steam. High-pressure blowers can generate a very high air flow and simulate the operation of a fuel cell with an output of up to 350 kW,” explains Markus Kolczyk, Vice President Original Equipment Global Engineering at MANN+HUMMEL.

Humidifier test bench in Ludwigsburg - outside view

Humidifier test bench in Ludwigsburg - outside view

Comprehensive product validation and analysis for customer-specific reports

The test bench can set the important parameters of mass flow, pressure, temperature and humidity according to customer requirements. All collected data is stored in a database and used for AI-assisted training and calibration of simulation models. The evaluated data enables customer-specific reports and comprehensive product validation. Initial results show that the lifetime of stacks in fuel cell systems can be significantly extended by optimizing humidifiers – an important step towards cost reduction and scalability, making fuel cell technology even more attractive for various applications, especially for hydrogen-powered transportation.